Calculation Of Allowable Fatigue Strength Values For Welded Joints

The allowable stress values that are used to determine the utilisation factors in general need to be calculated, depending on the thicknesses of the connected sheets, the stress ratio, the weld material and the assessment standard. WeldFEM conducts these calculations using the information given in the settings and the FE-model.

The particular steps for the calculations are explained for a distinct example for comprehensibility in the following.

Example: Tee joint, realised as one sided fillet weld. The weld material is EN AW 6060. The thickness of both sheets is 12,5 mm.

Step 1) Set Up Material

The first step consists of setting up the right material in the Options GUI. Always make sure the material characteristic values, safety factors and mean stress sensitivity, are correct.

Step 2) Select MKJ-Curves

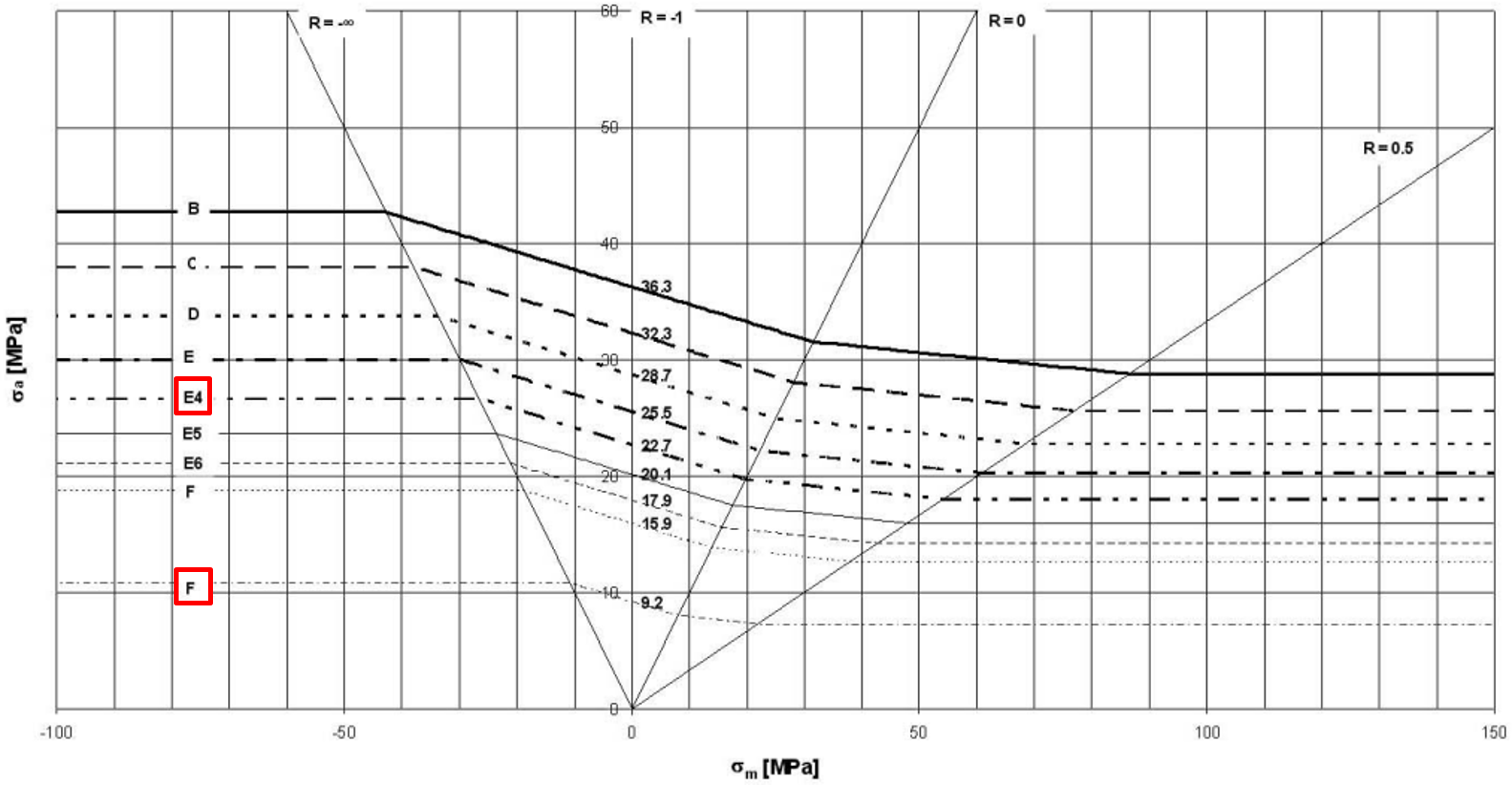

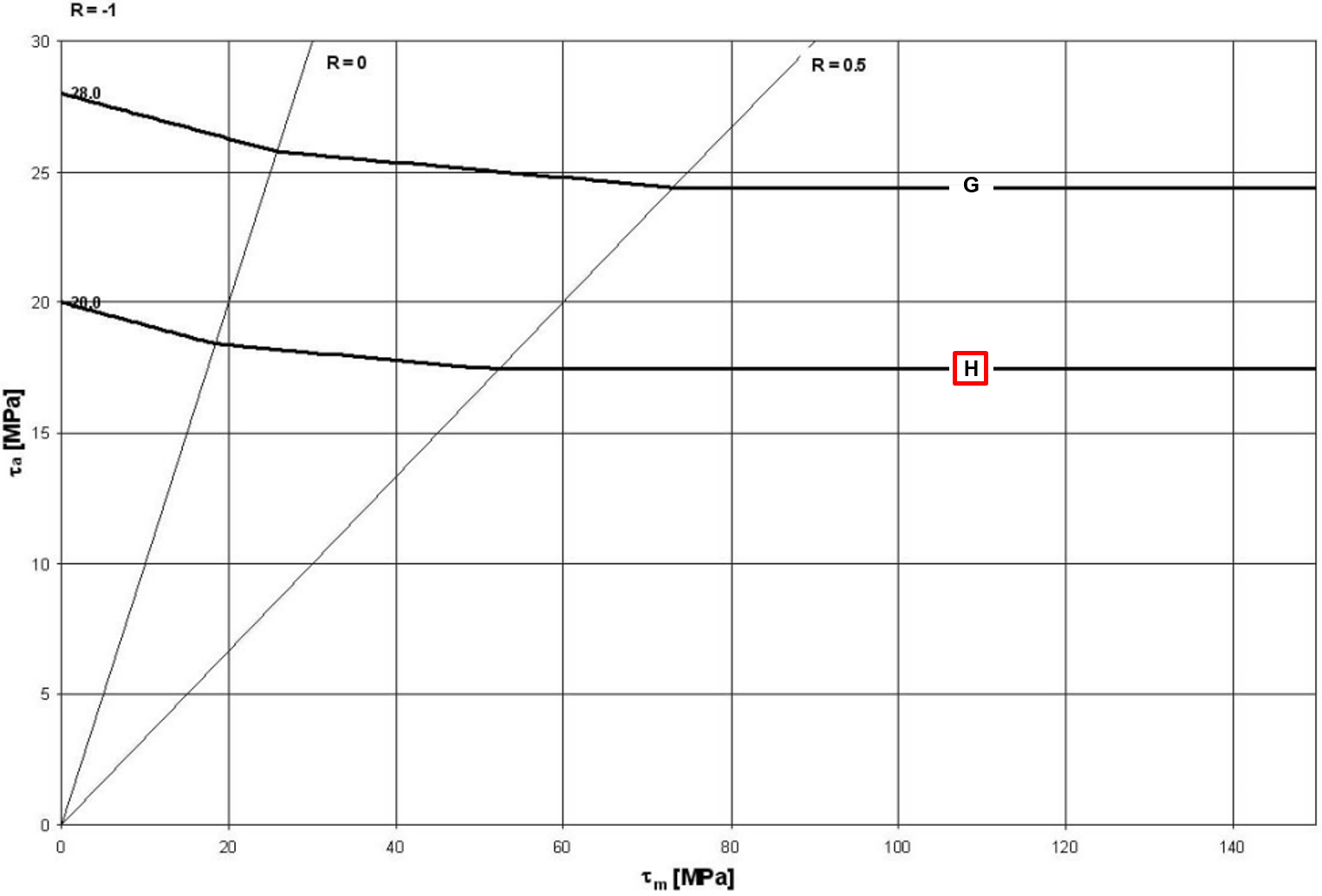

The second step includes defining the MKJ-curves which match the notch case. For the fillet weld the most conservative MKJ-curves for the perpendicular normal stress component is F2 and for the parallel normal stress component E4. The shear stress MKJ-curve is H.

The corresponding exponent x of the selected MKJ-curves for normal stress are x = 41 for F2 and x = 18 for E4.

The corresponding exponent x of the selected MKJ-curves for shear stress is x = 9 for H.

The MKJ-curves and Haigh-diagrams used are shown below. The graphs were taken directly from the DVS 1608.

.png)

.png)

Step 3) Determine The Stress Ratio

The third step includes determining the maximum and minimum stress values, in order to calculate the stress ratio. For the purpose of this example a general stress ratio of Rσ=Rτ=-0,7 will be assumed. Note that this has to be determined for every weld element and over all selected load cases.

Step 4) Calculate The Allowable Stresses

The fourth step includes calculating the allowable stress values for normal and shear stress components according to the formula given in the DVS 1608.

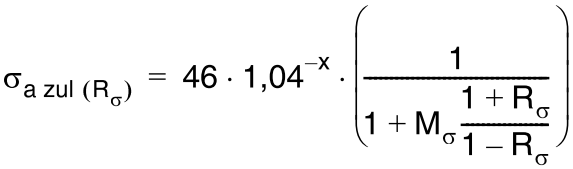

The allowable normal stress value can be calculated by following formula:

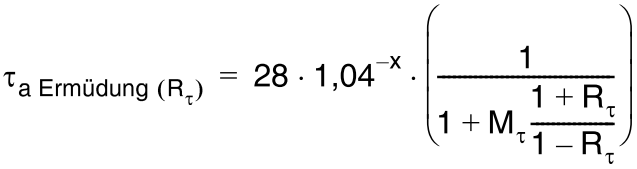

The allowable shear stress value can be calculated by following formula:

With Mσ = 0,15 and Mτ = 0,09 (Mean stress sensitivity specified by DVS 1608) the allowable stress values are σ⊥,zul = 8,98 MPa, σ||,zul = 22,12 MPa and τzul = 19,35 MPa.

Step 5) Consideration Of The Sheet Thickness Influence

Since both of the sheets posses a thickness greater than 10 mm, the allowable stress values calculated beforehand need to be down scaled.

This is done according to the following formulas: ![]() ;

; ![]() ;

; ![]() .

.

Therefore the new allowable stress values are σ⊥,zul = 8,78 MPa, σ||,zul = 21,63 MPa and τzul = 18,92 MPa.